The Smart Warehouse With Dan Gilmore

Want to know how you can deploy a smart warehouse for your business? Today’s guest is Dan Gilmore of Softeon, a company that provides a full suite of flexible and robust end-to-end supply chain software solutions to deliver success. He joins Joe Lynch to talk about the idea and technology behind their system. They discuss some of the big trends impacting warehouses, e-commerce, and retail. From labor shortages to automation, Dan enlightens on the benefits of WMS and WES for any business. Tune in to better understand the perks of this new smart technology for optimizing your business!

The Smart Warehouse With Dan Gilmore

Our topic is the smart warehouse with my friend Dan Gilmore. How's it going, Dan?

It’s great. I’m happy to be here.

I'm glad I'm finally getting to interview you. Please introduce yourself, your company, and where you are calling from.

I'm a Chief Marketing Officer of a supply chain software company called Softeon. Our company is headquartered in Reston, Virginia, outside of Dallas Airport. I happen to be in the Dayton/Cincinnati, Ohio area.

What does Softeon do?

It's a supply chain software company, primarily a supply chain execution. The company was founded in 1999. Our first customer all the way back then was the L'Oreal, and we proceeded to build out a suite of solutions that were brought in deep capability. That includes warehouse management systems, and all the stuff that goes around warehouse management systems including labor and resource management, slotting optimization, and yard management.

A newer thing which we will get into because it's critical to what's happening in terms of the smart warehouse is something called warehouse execution systems, which have been around for a while but gained prominence in the last couple of years as a way to optimize and orchestrate order fulfillment level at a capability that's beyond even very good tier ones.

This category of stuff is called distributed order management, which has to do with the optimal sourcing of products based on customer commitments as well as network capacities constraints in how do I get the lowest cost alternative that meets the customer needs? It’s a very prominent in omnichannel commerce. It is almost essential in retail but we are having a lot of B2B type of successes in distributed order management as well. There are some other things that could give a flavor to what we do.

You started well before eCommerce was a thing. Do you still support stores and that kind of warehousing?

Traditional WMS type of capabilities for retailers, would largely be store replenishment. Now, we are moving into eCommerce fulfillment. Many retailers are also looking to have a lot of activity at the store level, whether that's buying online, pick up in-store, curbside pickup or store fulfillment. We've got some solutions there, both in terms of the distributed order management that I referenced.

It is the tool going that says, “The best place to fulfill this order from based on the time commitments as well as inventory availability, labor availability, etc. is store 3, 4, 5, 6, 7,” and then have the ability to first identify where it's the right location. That could be obviously a DC, a third-party facility or something like that. The first word is the best place to source it from, and if it's a store, we have a store module that facilitates the inventory transactions, picking transactions, and shipping at a store level.

That became a thing. Target is one of those companies that if you buy something online from them, they are more likely to ship from their stores these days.

I have seen and the figure keeps rising.

The whole market has changed. The more high-tech feel and touch, the less back-breaking work and less bending over and lifting heavy cases.

It’s like 80% or 90%.

Let’s say 90%. That's the number I had in my mind too. They are doing them from the store, which is incredible.

Before we get into all that, tell us a little bit about you. Where did you grow up and go to school? Give us some career highlights and bullet points before you join Softeon.

I’m an Ohio guy. My whole life, I grew up in Akron, Cleveland area, and then got a job with NCR after grad school. I got an MBA from the University of Akron. I got a job at NCR that was here in Dayton. I was a Product Manager in charge of barcode and data collection. The way serendipity works, I moved from barcode data collection systems to wireless systems and then got into WMS. I was into consulting for a while. I have done a lot of marketing in the space. I was also Chief Marketing Officer at the Red Prairie before it got acquired by JDA and became ultimately Blue Yonder.

Earlier in my life, I spent a couple of years implementing WMS, a couple of major projects down here in the Cincinnati area that helped me learn a lot about how the technology works and what's good and less good. Notably, in 2003, I started a publication called Supply Chain Digest, which changed the face of online supply chain and logistics, news, and coverage. I still keep a light hand on it. I still write a column once a week still for Supply Chain Digest.

I have read that. I wrote a lot of blog posts in the past. When you are a writer, I have joked that “My research is a little different than a professor's research, I Google.” You start to realize which publications have good content when you are a blogger. The bar is a little lower for a blogger than it is for somebody who is writing in a publication. I would say, “Supply Chain Digest always had good stuff.” When and why did you join Softeon?

It has been a few years now. I had done a little bit of side consulting with Softeon before joining, and I was impressed with the breadth and depth of the software and the number of innovative capabilities, but as important as that is, lots of companies have good software. We think we've got leading-edge software but the approach to customers and success - I have never seen a company that consistently puts its own interests behind its customers on a regular basis.

We are not going to let anything get in the way of a successful implementation. That's a direct record that's unequal in the marketplace. It’s the care and concern for success at the customer level and not looking at everything through a lens of only professional services hours if I can sell or something like that. It was a different attitude. It intrigued me, and plus, the company needed some help in the marketing area to get that message out. The combination of those factors led me to join Softeon.

Our topic is the smart warehouse. Obviously, things have changed quite a bit in this business. Talk about some of the big trends that are out there that are impacting warehousing, eCommerce, and retail. It impacts everybody.

Most of the audience is going to say they are living this or these are big surprises but it's nice to still put it all in context, the growing distribution labor shortage and there's a shortage of manufacturing. It’s very acute. Everywhere you go, that's what you hear about the turnover levels, retention, and even with the greatest rising substantially. That's everyone's concern. After about a decade of very flat wage growth in warehousing and distribution until a few years ago, now, all of a sudden, the costs are taken off. Amazon has over $20 an hour with attractive signing bonuses in many parts of the country.

They now offer parental leave for twenty weeks. I saw it on TV.

That would be a very attractive benefit. That's the advantage. Target announced that they were raising their wage in both stores and distribution centers, not all markets but in some markets, by $24 an hour. That's $48,000 a year, and assume there's probably some overtime in there, whatever husband and wife are making up, for example. They are working at a Target DC in those markets, you could be pulling in $100,000 a year for a family, which is not bad money.

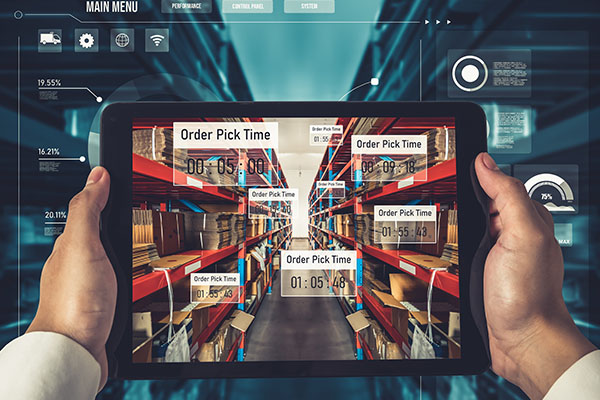

[caption id="attachment_7940" align="aligncenter" width="600"] The Smart Warehouse: With the e-commerce-driven cycle time pressure, it's unbelievable how fast you can get products these days.[/caption]

The Smart Warehouse: With the e-commerce-driven cycle time pressure, it's unbelievable how fast you can get products these days.[/caption]

This has come up on my show a few times. I’m getting too old for that kind of work, and I can't walk 10 miles a day but if I had a choice, we need to make that job easier. We are going to get to that because this is what technology does. It also makes the job more attractive when they can say, “I go to that job, and I'm learning all this cool technology.” If you can bring somebody in, there's a different feeling when I get to wear all that high-tech gear and use high-tech systems and say, “I'm part of the supply chain,” as opposed to, “I’m a strong back, walk 5 miles a day and nobody gives a crap about me.”

There are no questions about that. It's going to be both in terms of the shortage of labor and, second, building to attract people into this career. Now the whole market has changed, that more high-tech feel and touch, less back-breaking work, less bending over and lifting heavy cases, and all the kinds of things to go on and work for a long time. You are spot-on on that dynamic.

If we have a shortage, that means the people we do have to be more efficient. The way they can be more efficient is with tech. That's one big trend going on. What's another big trend?

There's a bunch in there that interrelated as well. Obviously, the eCommerce-driven cycle time pressure. If you look ay Amazon over your tablet, it's unbelievable how fast you can get products these days, even somewhat obscure products not that long ago, I need a new power cord for my HP computer. Somehow Amazon was able to deliver that the next day. I'm like, “Probably, they have this cable in someplace that they can get it to me one day.” Think of all the thousands of cables that are out there, and they've got mine.

The cycle time pressure in that both are in terms of getting the order process from when it drops into the DC and out the door. Obviously, companies are also moving distribution facilities closer to the customer, so the transportation part of the journey is cut down as well. They will remember the specific numbers. It's Home Depot that is building 170 or 180 different local fulfillment centers that are being the largely cross-dock type of facilities that bring bulky items in and get them right to the customer in addition to the big giant warehouses that they already have. It's a fact of life. Eventually, we will teleport or whatever the product from the warehouse because it seems like we are reaching the Laws of Physics there that it can't be here any faster but maybe we will find a way.

I remember, many years ago, I was working on a digital marketing project. I was helping this distribution center, nice, concise in Chicago land Peoria. They said we are one-day shipping to 65% of the population of the US. That was always what Indiana, Illinois, and there are so many DCs down in Ohio can always make that claim, and that was good enough. If you said, “I have a DC in the Midwest that can get me to the Eastern Coast, and I have one out West, that was good enough.” We are not seeing that anymore.

We are going to get increasingly where same-day delivery becomes a fact of life rather incredible. Amazon and others talk about getting it down to 2 hours or 30 minutes.

That's what Target is doing, not with those DCs. We think we will get to Walmart doing some of the same. What's another trend?

Obviously, because we are calling the session, we are going to talk about the smart and also the future but it's largely here nowadays. We’ve got smart everything. We've got smart houses, cars, refrigerators, and toothbrushes even. I saw that a couple of years ago. I'm not sure if it's exactly taken off the map but to monitor how often you brush your teeth. What does it mean? Primarily, it's talked about internet connectivity and some analytics around that. The least examples are John Deere, Caterpillar or companies of that kind, putting sensors and other IoT types of devices on their equipment out in the field so they can get a sense of how people are actually using it.

They can do predictive maintenance on it. They could say, “Your guys aren't using the equipment as effectively as they could if they changed their techniques.” It's certainly timely. If we are going to almost start things where it's time for the smart warehouse too but we will get into for the rest of the broadcast era left different than more internet connectivity, sensors, and things like that.

That can be part of it but it is a small part of it. The bottom line of it is we are entering a new era of where all soccer technologies that are, in fact, much smarter than we have ever had before. I have argued publicly for a couple of years now that we had about twenty years of relatively incremental progress in WMS technology.

I used this in speeches before but a few years ago, I was cleaning up my office and running the holidays as I often do when I found an RFP from a major food company for a WMS circuit in 2003. I looked through that and I thought, “This doesn't look all that different than the RFPs we are seeing in 2019, 2020 or whatever year we are looking at that.” I looked at it and said, “The big difference is not in the functionality being asked for. It's that now, a lot of that functionality is, in fact, core product, configurable product than maybe a lot of it had to be achieved through customizations.” That's probably true.

Same-day delivery has just become a fact of life.

The fundamental way of where WMS operates didn't change all that much give or take from 2000 to 2020 or somewhere in that range. Now, with the smart technologies that we are talking about, they are brought by the world's execution systems in working with WMS, I talked about before. This is a new ball game, and it was going to be fun for the rest of the people here to talk about this.

You throw in a new term there. You said warehouse execution system. Those have been around for a while but they are now becoming the norm.

It's becoming very prominent, and then the value is starting to be recognized.

What is it?

A couple of three companies had the belief and correctly, for most of the WMS systems did not care enough about equipment throughput and utilization. We wound up with big peaks and valleys, and anybody have been in a district distribution center, even a busy one. You have seen it where there are all kinds of activity at the beginning and the middle of the wave, then as the wave starts to dissipate even on a big, expensive, huge sortation system, you've got a relatively small number of boxes moving around, waiting for that wave and everything to close out.

You said wave. Does that mean the orders come in waves?

Yeah. The work is released in what is called pick waves. That's based on any number of different attributes. It could be the carrier schedule, value-added processing that needs to be done or workload balancing across the different pick areas of the company. You organize the work against various attributes that constitute a block of work that's typically referred to as a wave.

I know I've got all these trucks that are going to show up and they are taking different orders, so maybe I'm working to that order that's going to fill up that truck. The problem, to your point, is we've got already may be a shortage of headcount in there. Now when we have waves, I'm not being efficient because I've got too much work at one moment and then not enough at another.

The whole goal of WMS of what we're talking about with the smart warehouse is overcoming, I mean, obviously, you've got to plan and execute based on the workforce that you have here, and we will talk about that.

Having a warehouse management system that gives me stuff was great in the past but you are saying, “I will help you with a WES or Warehouse Execution System. I'm going to help you manage the flow.”

Manage the flow work and the resource utilization, and then new ways. Part of that still ties into that interest in level loading or making the flow of goods across an automation system more smooth and consistent because if you can do that, there are a couple of things. First off, the total throughput of the system is likely to be better.

Second, if it's a new facility, you could probably get by with a smaller sorter because you are going to be able to utilize it more consistently over a block of time, a shift or over what you want to look at it there. The other breakthrough that Softeon said is that the WES tends its roots and level loading of the automation and better utilization there. The WES works extremely well, even in non-automated facilities or lightly automated facilities.

[caption id="attachment_7941" align="aligncenter" width="600"] The Smart Warehouse: The fundamental way a warehouse operates didn't change all that much from 2000 to 2020. But now, with smart technologies, this is a new ball game.[/caption]

The Smart Warehouse: The fundamental way a warehouse operates didn't change all that much from 2000 to 2020. But now, with smart technologies, this is a new ball game.[/caption]

As a matter of fact, one of our leading customers did a press release a couple of years back that talked about 50% productivity gain from implementing WES or Warehouse Execution Systems on top of existing Softeon WMS, and doing that in a totally manual environment. Everything is part of a system. You can have a sortation system, goods to person system or put wall system or whatever. It's got a certain capacity, throughputs, inputs, and outputs.

Twenty workers walked around on a three-level case pick module. There are systems too. They have inputs, outputs, throughput, and expectations. The one big difference is that with a more manual system, you can throw more bodies at it up to the point of diminishing returns and gain through the port from that area, whereas a heavily automated system is rate as its rating. You are not going to do a whole lot to affect that.

Throughput is everything, whether you are a plant, a freight broker or a warehouse. The stuff that goes out the door and that we can charge for is what we want to do. Having a warehouse management system is great. I know there are certain warehouses. Probably the old ones still don't even have that. You are saying to be as efficient and effective as you need to be in the market, you need a warehouse execution system that gets me the flow and that throughput.

It may not be for everybody, and there are certain things you can do. We could take your core WMS and add some select capabilities from a full-blown WES if a modest level of that kind of automation is necessary. It's not necessarily for one, and I don't want to position it that way but it's certainly something that you want to take a look at as you get to where you've got a significant number of workers. Even smaller operations, things like the automated release of work to the floor without the human being need needing to be involved, that's going to be attractive even for a mid-size operation.

The first thing we need is we need to get into this. WMS is given. You said that there was an incremental improvement for many years. Now, you are starting to see big improvements that may be driven by the market that needed big improvements in recent years. Part of that is this WES. What else is there that’s part of that smart warehouse?

There's a whole bunch of stuff. First, as a reminder, the automation because automation is tied to the labor shortage. Even a couple of years ago, it was very common to talk to DC managers or logistics executives, and automation wasn't necessarily very high on the radar. Nowadays, almost close to 100% of the companies we talked to, even smaller companies, are looking at automation of some kind. That could be big automation where you've got traditional sortation systems but can be very large, goods to person systems, those kinds of things. There's also a lot of interest in lighter, more flexible, and less expensive technology things like what are called put walls.

What’s a put wall?

In great simplicity, it is a technique or a structure, which is a module with a series of cubby holes or slots. In one of these modules, we have 1 customer that has 80 of these modules. What you do is you pick the orders, then when you come to the put wall, you distribute the order to the different orders that need that product. I batch pick the product.

I bring it either mechanically or manually to the put wall. Typically, a series of lights says, “This company wall number 3 here and needs 1 of the skews. Put wall in. This one needs 2 that skew you put two in. This one needs 1 put 1 in.” That process repeats itself until all of the items for a given order are complete within that cubbyhole.

That's called putting. That's why it's called a put wall because you are taking the order in back, and then you are putting it into the put wall. Around the backside, lights will turn on that indicate, “This cubbyhole is now complete.” The operator comes up and touches a button typically. That starts the printing of the label in any shipping documentation that's required in the orders packed, shipped, and off you go. It provides a tremendous amount of productivity. It’s very flexible. You can start small.

We had one customer that started with a 1-foot wall module, then added 8 or 9 more because they liked it, then they added 20 more because they really liked it, and did this all over a couple of three-year types of the period there. For any kind of piece picking, especially of soft goods but other types of products as well but often driven not only by eCommerce with any kind of heavy piece picking operation can be a great solution but you’ve got to have the right software to do it.

You've got that big like almost a shelf you said like cubbies on that I'm putting a product through it. Maybe I walked over, and I got 10 different sweaters, 10 sweaters that are all the same, and this cubby gets one. As I do that, I'm scanning it or it recognizes that it's in there. It's informing the other side of the cubby when the order is complete. It needs two sweaters and a pair of shoes. That's just one more way. What do you call this? Technology is only part of it. The other piece of the cubby that walking up to that, I could be putting those in bins in the old days but this is putting that on steroids.

The bottom line is we are entering a new era where all technologies are, in fact, much smarter than we've ever had before.

It was just a new way of doing it. There are a lot of people who talk about this in terms of optimizing materials and handling systems because getting this right is not a trivial task. I don't want to steal all my thunder from later on but the ability to rapidly turn these put walls and cubbyholes are the whole key to the success. If it's taking you a long time to do that, you are not getting the throughput that you required and probably wasting your time and money but if you can rapidly turn those by making sure the inventory gets there on time and efficient execution on both sides of the wall, then you've got something that can drive a lot of productivity.

I don't know what the number is. There are quite a few customers now that are using put walls. When we would go out to some new customers, we've got some videos to show them an operation, and they are interested in seeing how this works. It's the technology along with mobile robots that you are going to see, any eCommerce but any kind of piece picking as well, you are going to see a lot of adoption.

I’m an automotive guy originally. When you used to go through a plant, you would see people doing lifting heavy things when I first started, crouching down and doing functions that were hard on the body. Maybe it's not hard on 1 day, 1 week or 1 month but over 1 year, you are going to have a bad back, shoulders or knees. The same thing happens in these DCS or the warehousing. This automation you are talking about is making it easier on the workers, which means, “Hopefully, I will be able to keep my workers healthy and make that job again more attractive.”

One time, I talked to a VP of logistics at Sherwin-Williams, the paint company. He noted that on the manufacturing side of the operation, they were always having people retire, and during retirement, little parties were almost taken. He said, “There was no one that ever retired from the distribution side.” That's because the heavy worker is picking cases of paint as a young man's job. As people got older, they couldn't do that work anymore. People are obviously rethinking that for the aging factor, and then there's another factor, “How do I make the work easier so I can have somebody in their 50s and 60s continuing to do this at distribution center job?”

If you gave me a choice to go work in an old school warehouse, go deliver food or deliver groceries, I'm going to do the grocery delivery. I can make decent money, sit in my car, and I don't have to hurt my back, or knees or walk 5 miles a day. We have to make these jobs more attractive or we are not going to be able to keep and get good people.

This automation is of such interest to the jobs now that we become more technicians and less of an order pickers.

Besides a put wall, what's some other automation you are seeing out there?

The automated mobile robots, economists mobile robots or AMRs. There's a huge interest in that. One of the interesting things is that in both put walls and mobile robots, you are seeing a lot of adoption and interest by a third-party logistics companies. This makes the point. In the past, 3PLs were very reluctant to do any kind of heavy automation because they couldn't sync the return on investment with the contracts that they had from the shipper. If the shipper can pay off that equipment, it’s going to take 5, 7 or whatever years, and the shippers only keep you where 2 or 3-year contract, the risk of automation is too great in these other kinds of systems.

It includes things like voice, picks the lights, and smart cards. They are all connected in some ways. Those kinds of systems can be put in for much less expense, much lower risk, and be incrementally adapted. You can start with three mobile robots and see how you like it, then we have seven more later on or whatever until you get to the optimal point for your operation.

The fact that 3PLs are making this kind of investment as a whole new phenomenon and it speaks to the way you can incrementally get into the technology and the high level of payback that they are seeing because we were very strong in the third-party logistics arena, as an aside, so we are seeing it very closely. The number of 3PLs that are interested in this mid-range of lighter picking systems, not heavy automation but it's often somewhat newer technologies. It speaks to the changes we are seeing out there in the marketplace.

Those are robots. Depending on the facility, they are not necessarily always replacing people. I talked to the CEO or president of DHL. He says, “We thought we would be replacing people with robots. The more robots we add to a facility, the more work we end up getting for that facility. We ended up hiring more people.”

Everyone has a shortage. Job is going unfilled. If the robots are taking some of that slack but very few case studies of people that are adopting these technologies, they are still looking for people who have been able to be on.

[caption id="attachment_7942" align="aligncenter" width="600"] The Smart Warehouse: WES (Warehouse Execution System) will help manage the flow of work and resource utilization.[/caption]

The Smart Warehouse: WES (Warehouse Execution System) will help manage the flow of work and resource utilization.[/caption]

What's another thing we need for that smart warehouse?

Let's get into it in some more detail. We talked about some of the core software components, things like warehouse management systems and warehouse execution systems. A platform for integrating this automation with both heavy and/or traditional and newer age capabilities. There are some enabling technologies, things like rules engines, simulation and some other things. The core world's operations excellence is still the foundation. How do I get that right? That typically involves traditional WMS-type capabilities. What does that mean?

What defines a warehouse management system versus an inventory system is the pervasive use of mobile terminals, barcode scanning, wireless RF devices or whatever term you want to use there, and then a lot of system directed activity, this whole notion of task management and task monitoring, where the system is orchestrating the different traditional paths of put away, receiving put away, picking replenishment, etc., and support for multiple strategies around that.

We have lots of different picking method options, different replenishment strategies that I can use, and things that have been around for a while like slotting optimization, detailed labor management, labor reporting, and things like that. The foundation is core operations excellence. That's what everyone should strive to get to but nowadays, there's no ability to take that even further in terms of different types of capabilities that we think are defining what we are calling the smart warehouse.

You used a term there that was an integration platform. What am I integrating?

You were integrating primarily different materials handling technologies. That can be things we have had for a wall that conveyor transport and sortation. It can be some of these newer technologies like robots and put walls. The key is, “How do I optimize the flow so I don't have these islands of automation that are all doing their own thing.” I talked to somebody in the apparel industry. They have a very large and highly automated facility somewhere down in the Atlanta area. It’s 1 million or 2 million square feet. They are seeing their throughput from that building after huge investments over the years and over time.

They are seeing the throughput decline. What's happening, he believed, is that the business keeps changing. They keep having all these new requirements in terms of how an order needs to be processed. What they do is they keep building new wave types. We talked about wave planning before. Now they are up to like 70 or 80 different wave types. Every time there's another problem, wave fight number 82 if that solves our problem, it's not solving the problem.

Part of the reason is that the system is not looking holistically across the facility and seeing how I can optimize the flow of work as a whole, not as an individual subsystem. That's part of what we are talking about here with the smart warehouse. That's the thing that traditional WMS has not done.

That integration platform means I can connect all the tools and all the different systems I'm using all connect easily through that integration as opposed to the old way, which is a standalone $100,000 integration with expensive people who have to code.

That's certainly part of it. It's managing the flow of work across that. I'm getting hit myself again but for example, you can have some scenarios where I have different paths for an order to be fulfilled. One of the paths and the most efficient for certain orders is maybe a group of put wall models. Let's say put wall area, for whatever reason, starts to be congested. All of a sudden, there's a big backup on the conveyor feeding into the put wall area.

The system is going to automatically recognize that. For some time, route orders away from the put wall into manual cart picking, which takes them to the packing station, the same packing area where the put wall automotive leads. When the congestion is clear, then the system automatically reroutes that work back to the put walls again. Now you are looking at only the plain integration but in monitoring the flow of work that's happening and making real-time decisions accordingly.

I’m an automotive guy, and we had all of those years. We used the term smart factories, and it was the same thing. How do we increase throughput? What can happen is you can end up with a local optimum where some guys are building a big stack of inventory and does nobody any good? What does all that excess inventory doing for me? What makes more sense is to say, “We are going to get this, so there's a flow to it. We are not building up too much inventory. There are no bottlenecks.” This is the same thing. What you are talking about here is, “How do I arrange my people so I don't have these guys sitting around because they already finished while these guys are in a congested area?”

The core world’s operations excellence is still the foundation.

The term flow manufacturing came out of exactly what you are talking about there and was largely developed initially in the automotive industry. We are talking about the same thing. Now we are talking about flow distribution instead of flow manufacturing but the fundamental concepts, more of a pull-based system were being worked on capacities and constraints, more concerned with the total flow of goods and not what's happening in one individual area. All those are very consistent, whether you're looking at the principles that were established earlier in manufacturing or what's being applied here in distribution.

I'm going to assume that at one time, the WMS, a big selling point would be, “We will tell you where your inventory is at,” That was probably a big step up. You go, “It does that. Now I'm going to tell you how that inventory moves off of your shelves and out the door and how you bring new inventory.”

It's amazing. We still see quite a few every week, we see somebody that's a calling or emailing in, and then we talked to him. It turns out they don't have that real-time visibility of the inventory because they are using some kind of paper-based system or something, and sometimes these are even good size companies. In general, anybody that's implemented a tier-1 or tier-2 level, even WMS shouldn't have that real-time inventory visibility in doing that.

It gets into that operations excellence and problem but that's the foundation, “I got to know what I got and where it is by lot, batch, serial number or whatever attribute is important for your operation or combination of attributes.” That's the foundation, but now, we are saying, “How do we optimize on top of that and get more product out the door and lower cost?”

It requires investment. Having a WMS tell me, “Here is the information but it's not enough anymore.” To your point, we need all of this to get there.

You asked me about some of the components of the smart warehouse, and I talked about it from a product category perspective, but now, I'm talking about it more from a philosophical or a functional view. One of the key foundations is constraining condition awareness, “What's happening in my building? What's happening with the flow of goods?” One of the things that first got me to understand WES in a deeper way is this notion that it's always-on listening and monitoring the environment. If you think about a traditional WMS, it's more sequential-oriented, “I receive the product. I put it away. I replenished pick sites. I do the picking. I take it to pack or evaluated services. I put it in this receiving staging. I get it shipping staging. I get it out the door all very good then the delivered.”

A lot of companies don't have that. Organizing and automating all of that are big steps forward but we need to take it to the next level. If you think about this notion, the system is always on monitoring throughput and flow. There are certain rates and throughput that I'm expecting. I need to be able to have a flexible set of dashboards supported by event alerts and notifications. If there's a problem that says, “Here's what's happening across.” However, I wanted to find it in the area, I can define an area as a case picking module or as a whole three-level case pick module.

I see that as one unit, and I want to know what the throughput is there. Maybe I want to see it at each level of that pick module. I can see it more gradually. What's nifty about this is that new level of visibility, the activity, throughput, bottlenecks, alerts, and corrective action automated, increasingly automated, if there are bottlenecks.

That provides a nice set of real-time dashboards of looking stuff where people can see what's happening, “I have these many orders pending here that’s already been completed. Here's how many are in picking,” or all of that level of detail. To understand what's going on here with the smart warehouse is, the system is using that same data that's being exposed to managers and supervisors that’s what it’s using to make decisions as well.

I decided that example of being aware of the backup that's happening in the put wall and automatically, for some time, routing work around that until the congestion is cleared. That's what's different now about this visibility and activity monitoring. Being able to flexibly do that however you want to define a processing area could be evaluated services. It could be peace picking and all these things.

Obviously, now the design is at these different flows throughout the facility are in sync. I'm not getting old backed up and packing, which is causing problems way back, picking and replenishment because I haven't automated the visibility and the flow, release in a way that's going to be cognizant and aware that I've got a problem here and, “Here's what I need to do about it for some time until we are adjusting. We are just taking action to solve the problem.”

You sent me a PowerPoint and I have this here. It's got that real-time configurable dashboard. It's been a while since I have seen somebody had me a piece of paper but somebody handed me a piece of paper that had 40 columns. It was like an Excel spreadsheet or something, maybe a spin out of a system. It had so much, I looked at it and I was like, “What am I supposed to do with this?” I liked the idea of being able to configure it for those KPIs that I care about.

[caption id="attachment_7943" align="aligncenter" width="600"] The Smart Warehouse: One of the things that got me to understand WES in a deeper way is this notion that it's always on, listening and monitoring the environment.[/caption]

The Smart Warehouse: One of the things that got me to understand WES in a deeper way is this notion that it's always on, listening and monitoring the environment.[/caption]

I don't want to measure everything. That's just me. Tell me the 4, 5 or 7 things that matter that tells me my warehouse is moving in the right direction, and that things are working well. It says, “Orders with issues.” I also love the idea that I don't find out about the issues in next week's report. I find out about them in real-time.

The point that you made is a nice transition to this notion of another component. We talked about the real-time visibility of capacities, constraints, the conditions up there, and the always-on nature of the WES. Now, we have talked about looking at a table of 40 rows of information or whatever.

It's all in the past.

It brings up a point there, which is even with higher-end WMS, this is one of the learnings and insights that we have. There's still a tremendous amount of decision-making that is being done by human beings. As the manager, whoever you were talking about there in your example, staring at a 40-row spreadsheet or whatever, you see the same thing nowadays of managers and supervisors staring at computer screens, trying to figure out what the right thing to do next. Here's the reality. Every time you do that, first off, you introduce some latency into the system because it takes time to look at those different screens, think about it, make decisions, and scribble some things down on a piece of paper to remind you this needs to be taken care of or whatever.

In most cases, there's no way a human being can make the optimal decision in the same way that a computer can. Even if you are a smart guy or girl, there's just too much data and too much to try to process at one time. Part of the capabilities of the smart WMS is the much more advanced software-based decision-making. Things like order batch optimization, given block of orders, “What's the best way to most effectively execute that on the software floor?”

What we think is absolutely huge is this notion of the autonomous warehouse, as a term of Gartner is used, and others have used it as well but it talks about being able to automatically release work without the need for a wave planner, inventory expediters or all the kind of people that you see often involved in these decisions about what work to do when. Work relation on a variety of attributes, things like the order of priority, the inventory and resource availability, what kind of optimization opportunities are there?

The bigger the order pool and more optimization opportunities you have because they are more data or conditions to be optimized but you can't hold on so long. You are not getting the throughput out through your cutoff time. This is a huge one. It's sophisticated. Whereas now, at 4:00 or 5:00, when the UPS, FedEx or whatever truck is leaving, you often see, and we have made commitments to the eCommerce is going to ship, you see a certain amount of chaos going around, trying to figure out all the orders that need to go on that truck, have been on the trucking and what to do about it.

What we are talking about here is we are saying, “This is the work. We know how long it's going to take to pick and transport those orders to the shipping dock.” The work is going to automatically release itself. At the beginning of the day, we are more concerned about optimization. We still got a lot of decent amount of time, so we can focus on doing it the most efficient we can but as you go throughout the day, that needle starts to change from the focus on efficiency and cost to efficiency on customer service and making sure that those items are on there.

The system does that automatically. It's configured to take those into consideration. Now those orders are getting on the trucks automatically without the chaos and the difficulty that's going on out there. This is a step-change capability here. We are talking about a system that is self-learning and in optimal how releases work. This is another concept we have had in distribution software before, and this is what defines what works on the smart warehouse.

I had a boss in the past when I was young, I remember I sent an Excel spreadsheet to him, and it told a story. He's pulled me into his office and said, “This is a great Excel spreadsheet. I have to go through here and come to the same conclusion you did.” I go, “It's easy.” He goes, “No. When you send me this Excel spreadsheet, send me a recommendation. I don't want to have to come to a conclusion. That's your job. Show me that you attach the data back up but give me a recommendation.” I feel the same take way about running a warehouse, “Don't make me figure it out myself. Give me an alert that says, ‘This is a problem. This is how many orders are at risk. This is how many orders need to get on that truck that isn’t done yet.’”

To show you a simple example. Still, a lot of people, especially for eCommerce, are doing manual cart picking. I may have a cart that's got a certain configuration 3x3 or 4x4. What I mean by a 3x3 would be 3 shelves that each have room for 3 cartons each. I have nine total orders that I'm working on there. Most companies that we see do that are doing it with paper picking or pick by label or something.

There's some attempt to do that more efficiently but something as simple as cart picking. The smart warehouse can take it to a whole new level. First off, you’ve got to get this order pool that's out there and at any one period. I'm probably going to have done some cartonization logic there to determine what should go in what box, especially with a multi carton order.

In most cases, there’s no way a human being can make the optimal decision in the same way that a computer can. Even if you’re really smart, there’s just too much data to process at one time.

If you are shipping, for example, you don't want to put perfume in the same carton as payroll because of the obvious contamination that can happen there. When a picker comes up and scans a barcode on that cart, the system is going to automatically know it's this configuration, 3x3, 4x4 or whatever. It will have done some optimization typically in terms of what's called cluster picking were, “I'm going to take that cart to one location. I will put as many orders as I can on the cart that is signed to that cart that has the same set of skews so I can minimize my travel distance. Hopefully, I'm being clear on what that means.”

Now I get to that location that can be done with lights or it can be done with barcode scanning. It says, “Take one of these from this location, put it in the carton slot 3’1, which is the 3rd shelf and the first location. The next one is 3’2. 2’3, 2’1 or whatever that sequence. I'm doing that in a way that makes it very efficient but we can take it even still beyond that. What if a high-priority order comes on?

The pickers walk along as long as there's a location on that cart, whether it's a carton or a tote they are picking into. If it hasn't been started, we can remove automatically a lower priority order and insert a higher priority order that has come down onto that card as long as we would typically do it. The picker doesn't have to turn around and go backward as long as it picks for the new order or ahead of that picker. We do that without the picker, even being aware that it happened.

You can expedite automatically like, “I got a truck that's going to be here one hour. We haven't even started yet. Let's get this going.”

We say, “If you get an order in by 2:00, we will ship it that day. If it's 1: 58, all of a sudden, an order drops. I got two minutes.” This isn't going to automatically insert a higher priority order possible.

I like something you said in there that we talked about the labor problem with these guys walking around maybe 5 or 10 miles in a day. One of the reasons we are going to quit, especially if you are me, is I don’t want that many steps. When I walk over there, all my orders are in the same area, then I walk over here, and all my orders are there, as opposed to one side of the warehouse, and another order on the other side or I'm walking and go, “What has my life become where I walk back and like this?”

Order pool optimization as well because the bigger the batch that I'm working with, the more opportunities I have to gain those picks together. On a given card, I'm maybe walking a very few feet. To your point, and this is where you get into the whole notion of mobile robots because now, perhaps that, “I go to the pick location, I pick the order but I'm putting it on a pick card. I'm putting it on a mobile robot, and the mobile robots can move on to the next location or on the packing of the orders completed. I'm walking very little at that point or comparatively little, which is one of the attractiveness of mobile robot technology.”

Hopefully, it’s becoming clearer. The nature of the warehouse is changing, and a part of that's going to have to be to not only be more cost-efficient and get more out the door with the staff that I've got but it's making sure that people have a less miserable work experience and hence hopefully going to stay with this a lot longer.

This is not your grandpa's warehouse anymore. To be competitive, it used to be like, “These guys are high tech because they have a WMS.” Now we are starting to spin out the automation, the warehouse execution, and the integration platform. This is all getting really high-tech. Do you think this is probably the lowest-tech business there was many years ago?

House is all going to play out. It's going to be interesting to see but the lighter automation techniques, including the robots and the put walls, are so attractive in terms of their flexibility and expandability. There are machine learning, artificial intelligence, and all kinds of things going to be involved here. The warehouses are becoming technology centers. If you see the private equity money that's flowing into robotics firms, AI firms, and others, in a lot of the smart money, it’s the work that they do.

Companies, retailers, and other eCommerce companies are starting to realize the importance of a well-run warehouse. Was this guy’s quiet logistics? They’ve got bought by American Eagle. That was American Eagle recognizing the traditional retailer, the same thing we're going to buy ourselves a warehousing company because that's how important this business is.

The force behind what has become locus robots. We will move our vendors that happened because Amazon had bought key assist systems right before that and left a quiet without a partner for automation they were building the business on. They invented their own robot.

[caption id="attachment_7944" align="aligncenter" width="600"] The Smart Warehouse: What's really different now about this kind of visibility and activity monitoring is being able to flexibly do that however you want to define a processing area.[/caption]

The Smart Warehouse: What's really different now about this kind of visibility and activity monitoring is being able to flexibly do that however you want to define a processing area.[/caption]

Bruce Welty was at my show. He's the Founder of Quiet. He said he got a phone call saying, “Are you guys using those Locus robots?” He says, “Yeah, how do you like them?” “We like them a lot. Can we come to visit?” “Sure.” It was Amazon. Amazon looked around and said, “We love this.” They bought Locus.

A couple of other things I would like to bring up. First, broader use of some automation ideas or IoT type devices. RFID is starting to make something of a comeback years after Walmart tried back in 2003 or 2004. Generally, you are going to see many manual scanning activities that are going to disappear or if I need to move this way back now from being implemented at the store level by customers concerned with the eCommerce fulfillment for inventory equity purposes, you are going to see a move back up into the distribution operations. That will certainly be a big part of it.

We were already doing things like, for example, we are a broker with a pick cart. Picker with a pick cart can walk up to a fixed zone. The IoT automatically recognizes that this person is on. It automatically turns on the pick lights that are on those four pick locations. It's a minor thing there but that's an advancement we are going to see.

We have even done some stuff with congestion management and COVID, where we can tell exactly where somebody is in the I or using IoT and being able to assign work based on real-time visibility to who's closest to that work, but also when the COVID area being able to space people apart so that they don't get to say within 8 feet of each other, whatever that happens to be, whatever your metric you want to use, therefore that group constraint.

There are some various things that can happen there. This is still slow going. It hasn't taken off as fast as many people think but you are going to see RFID and IoT start to make some mural inroads over the next years. We have this follow the notion of Gartner and what's considered to be called a conversational voice. The transactional voice is doing the picking, pallet build or something using voice technologies. Typically, reading in a location check digit and doing a hands-free pick, replenishment or whatever the task might be but we're starting to get now into more of a dialogue.

We are all ready to the point now where we can have a supervisor take a smartphone and say, “Show me how I'm doing on wave number 235,” over a smartphone. That's going to bring back exactly what's happening now or, “Where's the replenishment for location on 3652?” We are still early in this game here but certainly, we will move to more of a dialogue going on with the WMS and WES than just playing transactional voice-type of technology. We ended with a very exciting where the future interface of the software is going to had.

This is where that integration platform you talked about comes in handy. I can connect to all this stuff. The new killer app that comes out, I can get it.

We have been left there. Automation and optimization of materials handling systems is certainly a key part of this. We refer to it, not just as a smart warehouse’s the future but as the smart automated across to the future due to the interest in the technologies we have talked about several times already. We can directly connect with these picking assistance, like walls, pick the light or voice without the need for third-party software.

Everyone else uses some kind of software from the put wall vendor, pixelate vendor or voice vendor, which adds another layer of integration and costs. It often results in people operating silos. We can directly control a lot of these materials handling technologies. It allows you to operate and optimize those in the context of everything that's happening in the world and all the information that's available, which provides you a lot of benefits over time because you are not just trying to operate in silos.

I talked to somebody that was using a pick-to-light system. They talked about how at the end of every week, they’ve got to go in and clean up all these pics that some of them never were executed in the pick-to-light system. I'm not quite sure why that is but it wouldn't happen with the way we are approaching things because we would be aware of that.

It probably has to wait on a real punishment. The problem is the pixelate vendor doesn't do replenishment the documents. You've got these silos going on here and there are a lot of opportunities. In terms of that integration platform, we think this is especially true for mobile robots, people are using the mobile software of the mobile robots.

What that does is it limits the total optimization that can be achieved but more importantly, you are now totally dependent on that robot software. What if you want to add different robots or change horses three years from now? There’s a better mousetrap that works faster or whatever that happens to be. Now you have become locked in.

We refer to it not just as smart but the smart automated across to the future.

We think the market needs a mobile robot and a broader automation integration platform. It’s almost like an operating system for automation in the warehouse that's going to allow you to have visibility to optimization of robots of different kinds from the same manufacturer of different types for different manufacturers.

You are not locked in. It's like a plug-and-play type of environment here three years from now. You can keep the robots or keep dependent you bought, but now, you want to add five more from a different vendor, plug them into this operating system, and have instant connectivity and the ability to optimize the performance. We think that's a much more low-risk approach going forward than locking yourself into a vendor that's coming to the software that's coming from the robot vendor.

Get back to the idea of a smart warehouse. It's all about throughput. If I have different systems that are connecting, that are doing local optimums, that's a problem because it's not supporting throughput. I always need that one source of truth. That's the main system that says, “This is all about getting stuff out the door here.”

I wanted to bring up one. Earlier, I talked about wanting to give an example of what the put wall. I referenced that as the cubbyholes in put walls. Here's the scenario we are seeing. Let's say there are three line items eCommerce order. Two of those line items in the order come from a carton flow rec area, that's very close to packing. I mean those orders are efficient to pick, in short distance to transport. The third line item is actually coming from a slow-moving mezzanine pick area that's farther away and is less efficient to pick.

If you don't do anything, otherwise what's going to happen in those first two items from that order are going to show up rather quickly, then they are going to sit and wait for 10, 15, 20, 45 minutes or whatever it happens to be for that third item on the pick, the order to finally show up. The cubbyhole has been tied up that entire time. What's the smarter warehouse way of doing it? What's the WES way of doing it?

Let's say it's 25% slower to go through the mezzanine or whatever the number you want to use it. We would release that third line item in effect 25% or 30% earlier. After the time it takes to pick and transport that as it's on its way to the pack station, now we release the other two orders line items in the carton flow rack. They show up at the put wall for processing at relatively the same time, and now I'm able to turn that wall without the latency that would occur if you didn't have smart software to do that. Hopefully, that's an example that makes it somewhat clearer as to how the optimization can affect operational performance.

You would never be able to get that done manually. It doesn't happen. This is like drinking from a fire hose. There is so much going on in this. Put a bow on this. Give us your final thoughts on this. What do I need to get to have that smart warehouse?

First of all, the benefit is it is going to reduce labor costs, have higher and more consistent DC throughput, you are going to reduce your need for automation in terms of things like the number of diverse or get more throughput out of the automation you have there. We didn't talk much about labor planning but that's a big part of it.

We can dynamically assign workers throughout the course of a shift from 1 to 8 to 9, 9 to 10, or 10 to 11 hours where are they needed motion and in what quantities, improved automated decision-making. It's an assessment. Certainly, if you are heavily automated, there are a lot of opportunities for you. As I tried to make the point earlier, even if you're only modestly automated or not automated at all, these capabilities can have some real benefit for your operations there.

The important thing to note with Softeon is these can be implemented very incrementally. I could implement a traditional WMS. Let's say I want the labor planning and allocation part of it. We can take that capability from WES and attach it to the WMS. To give you a solution, conversely, if you want to implement WES and leave your existing WMS in place, we didn't talk too much about that but that's a key dynamic. You need cartonization, which is a warehouse management function and even attach cartonization to that WES implementation.

Flexibility is key. That's what we try to design. We call it a shirt component library, where the applications can borrow components, functionality, and services from each other. We are pretty confident that it gives us a chance to understand what you are trying to accomplish, what your operations are like or whatever that some combination of these technologies is going to have a pretty good fit and take your world to a whole new level than we have seen over the last many years.

What's new over at Softeon?. What conferences do you go into?

We have done with the motor show, and it was a big success for us. We not only showed the smart warehouse, we presented the smart warehouse capabilities. We had a lot of equipment pick the light, other packing stations, etc., right on our routes. At the bottom of every hour, we did a presentation. We had consistently good traffic the whole time. We did a bit of an educational track and a session on the smart warehouse of the future available on Softeon. It was very well attended. That was good. We will be at the Gartner Supply Chain Symposium down in Orlando and then break after that.

[caption id="attachment_7945" align="aligncenter" width="600"] The Smart Warehouse: Even if you're just modestly automated, these capabilities can have some real benefits on your operations. These can be implemented very incrementally.[/caption]

The Smart Warehouse: Even if you're just modestly automated, these capabilities can have some real benefits on your operations. These can be implemented very incrementally.[/caption]

We finished up a series of educational broadcasts called the WMS Bootcamp, six different sessions on everything from building the business case to how to implement it successfully. It was a huge success, but all of that's now available on-demand. If they go up to Softeon.com. You will be able to find some links to that. If you have any interest in WMS, they're not commercial, educational sessions. You will find they have a lot of value. The feedback we got on it was outstanding.

I would like to watch myself because we went over this and it is gone from simple to more complex over time. I know you are simplifying it but to understand what's required requires a Bootcamp.

We learned a lot of lessons. I brought in some consultants and people that I knew and knew what they were talking about in terms of building the business case. We had some folks from Invista that came on and did that. I had some experience or exposure. I knew they knew what they were talking about. Some of that applies to some other consultants as well. It's a real nice series. It's non-commercial. If you want to learn some tips about how to get WMS selection and implementation, you'll find the Bootcamp serves you well.

How do we reach out and talk to you over at Softeon?

The way to get me is via email. My email address is